LUMiReader, LUMiFuge, LUMiSizer: dispersion analyser and particle size measurement

Demixing phenomena like sedimentation, flotation and coalescence are measured directly and simultaneously over the whole sample length with the innovative and patented STEP technology with LUMiReader, LUMiFuge and LUMiSizer.

Application: monitoring of product quality during the production process - rapid improvement of formulations - study of factors controlling coalescence and aggregation - acceleration of common aging tests - additional: optimization of separation processes - dewatering of sludge, removal of suspended solids - separation of products, additives and catalysts - cracking of emulsions (e.g. crude oil) - selection of flocculants, demulsifiers and their dosing. Accellerated shelf life prediction.

Application industries: bitumen, petroleum, crude oil, tar - colors, pigments and inks: paints, automobile, printing- and other inks, pigment dispersions - ceramic materials - cutting emulsions - food: baby- and infant nutrition, dressings and sauces, functional food, drinks, ketchup, milk products - pharmaceutical and cosmetics: liquid formulations, cremes, shampoos, toothpaste.

Publications, application notes: www.dispersion-letters.com

LUMiReader PSA / X-Ray

What is LUMiReader:

The separation analyser LUMiReader tracks separation mechanisms in dispersions at gravity. It records simultaneously the kinetics of transmission changes over the whole sample height with high resolution in space and time. Optionally it uses a patented tilt technology based on the Boycott effect to increase the separation velocity up to 10 times at gravity.

There are two models available. LUMiReader PSA allows the precise calculation of particle size distributions acccording to ISO 13317. It uses three wavelengths and therefore can do this even without knowing refractive indices. LUMiReader X-Ray on the other hand can measure changes in dispersions and in the sediment even at highest optical density by using X-Ray.

LUMiFuge

What is LUMiFuge:

The LUMiFuge is a microprocessor controlled, analytical photo centrifuge for rapid and traceable classification of stability and separation of even concentrated dispersions. It records the kinetics of transmission changes for 8 samples simultaneously, like a time lapse motion picture, at up to 2300 times earth gravity and higher space resolution than by naked eye. LUMiFuge has integrated temperature control from 4-60°C. SEPView, a databased software displays in real time the evolution of a large variety of demixing phenomena and qualifies sedimentation, flotation, aggregation, flocculation, polydispersity and shelf life for each individual sample.

LUMiSizer

What is LUMiSizer:

The LUMiSizer uses the principle of Centrifugal Separation Analysis to measure particle size, demixing and consolidation in one instrument. The "complete dispersion laboratory" analyses up to 12 samples at once. It combines a high end, PC-controlled centrifuge with a patented unique optics system (NIR or blue light source and a linear high resolution detector) to monitor the concentration profile over the entire length of a sample while it is being subjected to centrifugation. The Software is based on a comprehensive database solution. The analyser accelerates at variable speeds the demixing, allowing rapid stability testing and consolidation studies in highly concentrated dispersions in minutes and hours instead of days or weeks. It can also perform high-resolution particle size analysis according to ISO 13318-2 in the range of 10 nanometer to 300 micrometer (depending on physical properties)

PSI high pressure homogenizer with fixed geometry interaction chamber

Not for measurement but creation of the finest dispersions: PSI high pressure homogenizers with fixed geometry interaction chamber. For emulsification, deagglomeration, dispersion and particle size reduction. The standard unit was designed for food and pharma applications and comes with all certificates. Product contacting metal parts stainless steel 316L. The quietest in their class, compact, minimum necessary working volume. Working principle: wide range of fixed geometry interaction chambers, diamond coated. Therefore reproducable and scalable results (not to compare with variable geometry, adjustable valve, systems). Shell tube heat exchanger mirror polished. Hosing 316l mirror polished, Inbuilt micro-processor, displaying system for pressure, temperature and flowrate.

PSI 20: minimum batch size 150ml, flow-rate up to 24l/h, pressure up to 2000bar. PSI 40: flow rate up to 45l/h

GMP by Design, lowest noise, competitively priced

LUMiFrac: adhesion measurement

The clever alternative to a tensile tester with a very large measuring range, the (glued) samples only have to be placed in the measuring modules on the rotor, instead of difficult clamping. Only normal forces can occur, which improves reproducibility. 8 samples can be measured simultaneously, which improves statistics or allows quick comparison of different samples.

LUMiFrac is a novel instrument for the measurement of strength of bondings and coatings and winner of the Berlin Brandenburg innovation price 2012. Up to 8 samples can be but in easily and be measured automatically without clamping and adjustments. See a user video of the LUMiFrac by Bundesanstalt für Materialprüfung.

- Cyanoacrylates

- Epoxy adhesives

- Polyurethanes

- Anti-corrosion coatings

- Decorative coatings

- Metallized polymers

- Optical coatings- ...

- Alternating loads

- Changing temperatures

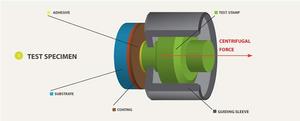

LUMiFrac working principle

Weight stamps are placed in guiding sleeves and bonded to samples to be tested. These assemblies are placed into the rotor, the lid is closed and the testing program started. For each sample the rupture and the corresponding rotor speed are automatically detected.

The advantages compared to classical tensile testers: a very wide measurement range, the samples only have to be placed on the rotor instead of difficult clamping, only normal forces can occur which improves reproducability, 8 samples can be measured at the same time which improves statistics or allows a fast comparison of different samples.

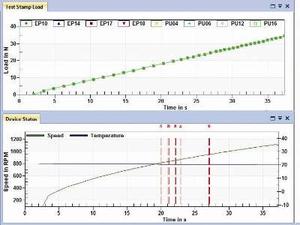

LUMiFrac Software

All data is transmitted to the computer and SEPView automatically calculates and displays the critical force/strength of failure in real time. Furthermore, it allows to analyze, compare & calculate statistics and to integrate fotos of failure patterns in the database

LUMiFrac Technical Data

Load range:

0.1 N – 6.5 kN

Tensile strength:

bis 80 MPa

Measuremen time:

1 min bis 99 h selectable

Conformity:

ISO 4624; DIN EN 15870

Number of samples:

up to 8 simultaneously

Maximum sample size:

30 mm x 30 mm x >1 mm

Adhesive area:

diameter 7 mm or 10 mm

Test stamp material:

metallic or non metallic

Weight of test stamp:

4.1 g - 38.7 g (W/Cu up to 58 g)

Unit dimensions (W x D x H):

38 cm x 64 cm x 30 cm

Rotor speed:

100 – 13.000 RPM

Weight:

56 kg

Termperature control:

-11°C to + 40°C