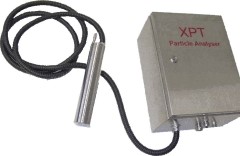

XPT - Particle size and shape distribution measurement

by dynamic image analysis

Online measurement of particle size distribution, particle shape, particle count. Just like a microscope where the particle stream is flowing through but that takes 30 images per second and the software does the complete evaluation at the same time: dynamic image analysis according to ISO-13322-2. The software is highly parallelized to measure and store the information of thousands of particles per second. The complete system with probe (XPT-P) or flow-through cell (XPT-C) uses a CCD Camera with extremely short shutter time or ultrashort light pulses for sharp images of fast moving particles. Here you find a scheme with the working principle of XPT

The XPT Software is used for all types of XPT units for automatic online image aquisition, particle size and shape analysis, trend display, storage of analysis methods, automatic saving of images and process integration. The software meets 21 CFR part 11 with hardware token for optional access control and electronic signatures for methods, analysis and reports.

The XPT-C systems with flow-through-cell for suspensions can be converted into powder measurement systems XPT-CP by simply echanging the measurement cell and adding the vibrating feeder. Other options are heated flow through cells for measurement of melts or polarized light for online distinction of crystalline and amorphous particles. For online powder applications XPT-CV systems with a venturi feeder sucks the sample through the measurement instrument and back to the process in a closed loop. XPT-P probes can measure directly in a process (pipe, vessel).